Correctly assemble the moonshine still. How does a non-flowing moonshine still work? Instructions for use

In ancient times, when the production of household moonshine stills had not yet been put into production, craftsmen made them by hand. After all, the first distillers appeared long before the formation of manufactories and factories - remember the same alambik. And during the years of Prohibition, when even simply making a homemade moonshine still was criminally punishable, the Russian people got out of the situation in the most unimaginable ways. And although it is now completely legal to obtain homemade alcohol, and the market is rich in a variety of models, homemade moonshine is still produced “on the knee” or on working machines during non-working hours. Some people prefer moonshine as a stand-alone drink, others prepare a distillate for. But the fact that the Russian people “have persecuted and will continue to persecute” remains unchanged.

It is, of course, possible to make a moonshine still with your own hands. Especially if these hands are golden. And getting the material you need these days is not such a problem. The recipe for making a moonshine still at home will, of course, be more complicated, but you will only be responsible to yourself for the quality of the distiller.

How to make a moonshine still at home

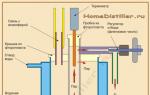

To begin with, let's define diagram of a classic moonshine still:

We have a distillation cube of the required displacement (from 10 to 50 liters to suit your taste and needs), a steam chamber (also called a settling tank), a cooler (or simply a “refrigerator”). The system is hermetically connected by a steam line, and at the outlet there is a receiving tank. The key word in the previous sentence is hermetically sealed. This must be remembered when making a moonshine still with your own hands. This is important to prevent the loss of alcohol and the release of vapors into the room, since most of them have an unpleasant odor.

How and from what to assemble the device?

First you need to decide on the material. Most often it is stainless steel with a thickness of 1 to 3 mm. But the thicker the steel, the more difficult it is to work with it without special tools and a machine. You can also work with copper, it is more flexible, but more expensive. Copper for food purposes is also more difficult to find, and then you will have to regularly care for it.

Element one: alembic. You can “cook” a cylinder of the required volume yourself, or you can use a saucepan (preferably a pressure cooker, it is most suitable for this, and the lid fits tightly). It is important to provide holes on the lid for hermetically sealed installation of the steam pipe and thermometer. The lid itself must be firmly attached and fit snugly to the cube itself; if it is not completely removable, then you will need to choose a silicone gasket ring.

Element two: settling tank (steam tank). Better with it than without it, although this element is not mandatory. The optimal dimensions are shown in the drawing.

Note that the connections of the elements of the moonshine still can be made from a silicone hose or using a stainless steel (or copper) tube. If you choose a hose, it is better to use silicone. It, unlike rubber, is inert and will not react with hot steam containing alcohol vapor. The final product will not have a “rubbery” taste or smell.

It is easy to distinguish rubber from silicone by the type of combustion: when silicone burns, white ash remains, and rubber smokes and emits black soot.

Element three: cooler (“refrigerator”). An integral part of the distiller, like the alembic. Here the vapor condenses, becoming a liquid. A refrigerator is a spiral tube with a length of 800 mm, placed in a container with cold water. The coil can be made from a copper tube or a tube for air conditioners; the coolant supply should be from the bottom.

Almost any do-it-yourself moonshine still involves metal welding. Stainless steel is welded in an argon atmosphere. It is important that the seam is smooth, ideally sanded. This is important to avoid leaks and corrosion. The desired dimensions of the steam pipe are 10 mm in diameter to avoid clogging.

Do-it-yourself moonshine still with distillation column

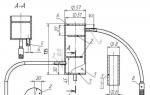

You can assemble not only a classic apparatus yourself, but also a mash or even a distillation column. Here it is important to maintain the exact proportions of the dimensions of the elements of the apparatus, since this is important for the optimal passage of the physical processes of rectification. Below is one of the design options for a distillation column with dimensions.

Element one: alembic. The column apparatus differs in its design from the classical one almost completely. Only the distillation cube remains the same. However, the column requires the same tightness when connecting elements and tight fit of the cube lid.

Element two: king. There is no steam room here, but there is a drawer. This is a vertical tube filled with a regular wire nozzle (RPN). The nozzle can also be irregular (bulk) - it can be twisted from small pieces of copper or steel wire, but you will need a lot of them. However, a regular nozzle works more efficiently and without any complaints. It is still better to purchase an on-load tap changer for the drawer, although some craftsmen use metal “scourers” for washing dishes for this purpose.

Element three: reflux condenser. The reflux condenser refrigerator (like the cooling refrigerator) has a “pipe-in-pipe” design, where cold water is supplied to the outer pipe.

Important: thermometer fitting. It can be located in the upper part of the drawer, or it can be located in the upper part of the reflux condenser (as is usually done by manufacturers of household distillation columns). It is preferable to place the thermometer at the top of the reflux condenser.

Element four: refrigerator cooling. It is a “pipe-in-pipe” design, but has a much longer length than a reflux condenser. The longer the path in the cooler, the more efficiently condensation occurs, and the product enters the receiving container cold, not hot. Alcohol losses in this case are minimal.

Important: connections. In the case of a column structure, a silicone hose can no longer be used as a steam line; all connections are made only from metal.

Welding such a structure is much more difficult than a simple “classic”; it requires solid skills in working with metal and a welding machine.

In general, creating a moonshine still with your own hands requires effort, time and significant skills. In addition, there is a risk that this will not bring savings, and even vice versa - this option cannot be called a budget option. (we recommend choosing a device with a distillation column of the brand) these days it has become much easier, and mass production makes the price very attractive. The choice is not so difficult to make, and thanks to this you will be able to clarify the nuances and hidden capabilities of the models that interest you.

Despite the huge selection of moonshine stills, many still make it with their own hands. This is done for the purpose improving the quality of the distiller And saving money, since some parts may already be in the household. We will show you several paths you can take to make a full-fledged moonshine distillation apparatus. We will consider the most fast, most cheap and the most qualitative option.

It is not always profitable to manufacture all parts of the device yourself. You can buy some things, but somewhere else it’s better to save money. We will tell you the most profitable options, and you will already choose the one that is most suitable for you.

I suggest immediately making a moonshine still with so that your drink turns out cleaner and of better quality. By the way, it is the steamer that is the part that is much more profitable to make on your own rather than buy in a store.

What does a classic and high-quality distiller for moonshine consist of:

- Distillation cube (tank). This is a container from 5 to 100 liters in which the mash is heated. It is best to make it from stainless steel or copper. Enameled steel will also work, but is less preferred. Food grade aluminum only as a last resort.

- Steam line. These are tubes through which alcohol vapor moves. They can be made of stainless steel or silicone. The main thing is that they are as airtight as possible and do not absorb odors.

- Sukhoparnik. A device for purifying moonshine from harmful impurities. It is highly recommended in moonshine stills, as it definitely has an effect. Most often it is made of stainless steel, but we will use a regular small glass jar. .

- Fridge. The most complex part in the design of the distiller, which helps cool the alcohol vapor and condense it into moonshine. There are several ways to make it yourself, although it is also available for sale.

Fastest option #1

Photo of a finished moonshine still from a pan

The distillation cube is a regular one, made of stainless steel or enameled steel. The steamer and refrigerator are purchased separately and are simply inserted into a pre-drilled threaded hole.

You can make such a unit in 10 minutes, and the total cost will be about 2,500 rubles.

Ready-made apparatus from a saucepan.

Turning a pot into a moonshine still

Simply cutting a hole in the lid and inserting a steam line there will not work; you need to make the pan airtight and dense. Only after this can you connect the refrigerator and steamer.

We perform the following actions:

A coil with a steam steamer costs around 2.5 thousand rubles.

- We buy a meter of silicone hose, cut it lengthwise and stretch it over the top diameter of the pan. This will be a homemade gasket that will keep the container tightly sealed.

- We drill a hole in the lid for a steam line with a steamer and a refrigerator. You will most likely need a 12mm drill bit.

- We insert the adapter into the pan, secure it inside with a nut and gasket, and attach our steam line to the outside.

- To press the lid as tightly as possible, use paper clips: clamp the lid and pan 6–8 times along the entire diameter.

- The distiller is ready for distillation.

Try not to accelerate the mash to maximum temperatures so that it does not begin to leak through the silicone gasket. Heat gradually.

Video instructions for making

Better to see once than hear a hundred times. Sixteen minutes author of Youtube channel Spy Gates tells and shows what actions and what tools need to be performed in order to make the device with your own hands.

This is a fairly budget-friendly and good option for all novice moonshiners for whom speed is important.

Cheapest option #2

Photo of the finished machine from a milk flask (can)

Finding it is not a problem now. Quite a lot of them remain from Soviet times, and even on Avito or Yule You can easily find a suitable option.

A flask makes a really good distillation cube of decent size, which is suitable for distilling a large volume of mash. It is not so difficult to process it into a moonshine still, because the principle remains the same as with a saucepan.

A possible option for implementing a moonshine still from a flask.

How to convert a can into a moonshine still

- Using a 20 mm feather drill, we make a hole in the can lid.

- We insert a brass fitting into it, which is tightly clamped from the inside with a nut and gasket.

- If you plan to monitor the temperature, you can make another hole under.

- We put a stainless steel gas hose on the fitting, which we connect to the steam tank.

- , read the detailed instructions at the link provided or further watch a separate video.

- From the steamer we move the hose to the refrigerator, which can be made flow-through or regular. The first option is more effective and complex, but for the second you just need a large container of water (bucket).

- Let's tighten all the nuts and start making moonshine!

For moonshine it is best to use. But brass is not the worst option either, so nuts made from this material are not a problem.

Making a distiller from a can on video

One of the most detailed videos from Youtube channel OverCraft collected almost 250 thousand views. The author shows all his actions on video and makes pop-up tips that describe the diameters and names of the necessary equipment.

The video is short, but it is enough to understand the general principles of processing a can into a moonshine still.

Making a steamer with your own hands

As a bonus, we are posting a video from Antonich and Alexey Podolyak, where the author makes a steamer from an ordinary can. You can even make one using this principle (filtration is through water), if it seems to you a more useful and effective device for purifying alcohol vapor.

We believe that any classic distiller should have 1 steamer or 1 bubbler. Combining them or making several at once does not make practical sense. Just wash unnecessary equipment and increase alcohol losses.

Highest quality option #3

Photo of the finished beer keg machine

The coolest device is made from. They require serious improvement and processing, but the result is at the level of high-quality and expensive distillers.

The most popular is the 30 liter container, equipped with. This installation allows you to distill mash in any room and place where there is an electrical outlet (even on the street).

Beer keg converted into a moonshine still. In analysis.

The process of converting a beer keg into a moonshine still

The work is complex and requires skills in using a welding machine, grinder and screwdriver. The sequence of actions is as follows:

- The hole on top for the steam line of the moonshine still is widened. A regular gas hose will not work here; you need a wide stainless steel pipe with maximum tightness.

- A 2-inch hole is drilled at the bottom for a clamp that needs to be soldered. In the future, a heating element will be inserted into it, which heats the mash.

- For convenience, a tap is cut into the keg to drain the stillage, the bottom is equipped with legs for stability, and handles are cut out on top.

- You can add a thermometer to the design, which is inserted in the same way as a pan and a can.

- Let's start the race!

The whole operation takes several days of work, since in addition to converting the keg into a distillation cube, you also need a steamer and a refrigerator.

Video instructions for converting a keg into a moonshine still

Prepared a wonderful series of videos Andrey Golubenko. Slowly, at home, involving small children in the work, the author slowly improves the design and ultimately makes a fantastic distiller that does an excellent job of distilling mash of any kind.

The process is divided into several parts, in each of which the author makes one of the parts of the apparatus design. We highly recommend viewing to all moonshiners for experience.

How to install a heating element into a distillation cube

A rather delicate task that can be solved in two ways: by welding or without her.

In the first case, simply drill a hole and weld a clamp into which we will later screw the heating element. The whole process is clearly shown in the video from the guys Steel Jet. The process takes a long time, but it is thorough.

In the second case, you need to purchase an o-ring and special ring from the online store moonshine-and-vodka.rf. This is a rather innovative method that no one has used before.

The guys carried out a lot of testing and released a unique product onto the market that solves a serious problem for moonshiners: the jaws periodically broke due to welding. Using a ring allows you to simply screw the heating element into the hole without unnecessary welding.

Other options for making a moonshine still with your own hands

Pressure cooker

The Soviet saucepan has perfect tightness, but an extremely small volume. Having filled 75% of this container, we will end up with a maximum of 1 liter of 40-degree moonshine, and in any case we will have to distill it twice to remove harmful impurities.

External view of the finished distiller from a pressure cooker.

You shouldn’t take this option seriously, but for a change you can try distilling an alcohol-containing liquid into it and see the result. Just try to clean the product as much as possible from fusel oil.

As an alternative to stainless steel tubes, you can use food-grade silicone. It is securely tightened with clamps and does not let anything through.

Multicooker

One of the most absurd ideas that could come into the mind of a moonshiner. It has excellent tightness and already has a valve for steam release. All that remains is to insert the steam hose there and you can distill the mash into moonshine.

A working moonshine still from a multicooker with 4 bubblers.

The video shows the distillation of wine and the remaining beer from the refrigerator. Several bubblers gurgle quite coolly, although such a number is not necessary, they look impressive.

As one of the users on Youtube rightly noted in the comments, the result was not ordinary moonshine, but a real hour! 🙂

Bucket

Finally the most crazy idea, this is distilling moonshine straight from a metal bucket. Tighten the seal using regular stops, drill a hole for the tubes and move on. Perhaps this is the cheapest moonshine still, which even surpasses a milk flask. 🙂

Distilling moonshine in a bucket.

It is best to use an enamel container, which will not react in any way with mash at high temperatures. Ordinary metal is not suitable for this, so take classic 12-liter buckets with enamel.

A bucket for 800 rubles will cost you much less than a stainless steel still for 5–6 thousand.

Brief conclusions

As you already understand, making a moonshine still is not so difficult. The distillation process is not that complicated, and modern distillers with high prices have only made it easier. And cleaner. Homemade distillers cannot boast of high-quality purification of alcohol vapor, although a homemade steamer solves this problem.

You're careful enough watch training videos And Don't make a mistake with the hole diameter, which you will need to drill or weld. You can leave any questions you have in the comments under the video. Some of the authors share their experiences with users almost daily.

Good luck with your work and high-quality moonshine after distillation!

I am not only a seller, but also a practitioner, a distiller with extensive experience. I personally worked on all the moonshine stills from my store and know all their strengths and weaknesses. Proof? Video channel Sur-Likbez .

Rest assured, all the mistakes were not pulled out of thin air, this is the experience of 3638 buyers, most of whom were novice distillers. So:

1. Think for a long time and collect information. Yes, of course, you shouldn’t rush headlong into the pool. Especially if you are completely off topic. But there is a lot of information on the Internet, it is contradictory and scattered. The more you read, the more confused you become and the less you understand which moonshine still is better.

Remember how you learned to drive a car. It seemed so unrealistically difficult. But as soon as we got behind the wheel and started driving, things got better. Right?

It’s the same here, because at the beginning of your journey you have no idea what you’ll encounter. Maybe you like distillate more than rectified or vice versa? You tried? At the neighbor's? What if you do better?

We can say that moonshine is one of the branches of cooking. There are a lot of nuances, directions, assumptions and almost no rules. Some people like it fried, some like it steamed. You put so much salt, I put so much, you put so much pepper, I add so much. Trying to study the theory completely and thoroughly, as in higher mathematics, will not work here. Understanding comes with experience.

Don’t think twice, buy what you like and make the first run. Only practice will give you answers to all questions. Even if you made a mistake, and the first moonshine still will soon no longer suit you. Rest assured, such a product will leave you quite quickly. Either on Avito or to a neighbor. This is me again, as the owner of a moonshine still store, telling you :)

2. Search miracle, so-called - " the best moonshine still" Unfortunately, there is none.

What is good for one distiller is absolutely unacceptable for another. I write more about the best device here. There is no such miracle of a device from which Hennessy flows. Success largely depends on you, how you follow the technology and select the ingredients.

But at the same time, due to the great interest in this topic, various “cool” and “sophisticated” moonshine stills appear every day.

The main task of such creators is to pump out as much money as possible from newcomers like you. Taking advantage of your ignorance and lack of experience, various fairy tales are composed on the fly, for example, some of them:

The double distillation apparatus is complete nonsense. I won't even discuss this.

100% clean. Explain to me how there can be 100% purification if the alcohol can only be 96%, huh???

Two steamers replace the second distillation. Is it really true, what about three steamers for a third? Absolute nonsense.

A moonshine still with five, six or ten steam chambers produces a crystal clear product. This will only lead to greater losses, but not to crystal purity.

And so on, go online and you will be bombarded with such offers. A fake product is easy to recognize; as a rule, it is sold through landing pages (one-page) sites and at the same time they promise simply unrealistic quality of the product. They also offer a bunch of useful and useless gifts + a 250% discount today only.

3. Want buy imported device. This is in some way a continuation of the second point. Here in Russia they make complete g... I’ll take an imported moonshine still, that’s where the quality is. Perhaps the quality is better abroad. But we don’t have imported devices in Russia.

At least in mass sale. You can, of course, find and buy something abroad. And the price will be appropriate. But those products with big names from European and Asian countries, which the Internet is full of, have nothing to do with imports. Well, perhaps, some parts for “European” moonshine stills are purchased in China.

Of course, among these pseudo-Europeans there are also worthy models and they can be considered for purchase. But only as an ordinary moonshine still, and not as an example of European quality.

4. Buy a device according to the principle: “ device for 5000(6000, 7000, etc. rub.) and that’s it. The rest doesn’t interest me.” Of course, I understand that everyone has their own capabilities. And besides, I’m not at all advocating buying the most expensive device. There are quite normal budget models. But it’s better to save up, rather than take outright nonsense, just because it’s cheap. Read what is hidden under a cheap moonshine still here.

5. Buy a moonshine still with small still. “What are you saying, I’m not an alcoholic, I’m doing it for myself! Why a big tank?! Give me the smallest one!” And at the same time theatrically rolling his eyes - a typical picture of a newcomer to my store.

Dear distillers, a 20 liter tank is FAR from 20 liters of moonshine, which you need to drink without a snack. Believe me, they still need to be made, and with a small cube it will take you a LOT of time.

The mash is poured into the cube to the extent of ¾ of the volume of the cube; you need to proceed from the planned production volumes. And strive to distill all the mash in one, maximum - two times.

Remember, a small cube is not a little moonshine, it is a lot of wasted time.

60% of my store’s customers who didn’t believe it and bought a small cube come back to buy an additional larger cube.

6. Don’t analyze yours before purchasing living conditions. For example, buy a column moonshine still and only find out at home that it rests on the hood. Such an irresponsible approach, although rare, does happen.

7. Check stainless steel magnet. Well, this is generally a bearded joke for me. Believe it or not, this still happens, people come to the store with a magnet. This is a method from the 80s of the last century, then it was relevant. People, it's the 21st century! There have long been grades of stainless steel that are magnetic!

8. Look for a moonshine still with the thickness of the metal is like that of a tank. Tell me, why is this necessary? Will the bottom burn out? Seriously? Think for yourself how you need to operate the device so that the bottom burns out. Will you really have such volumes? So that the mash does not burn. Again, thick mash should not be distilled over an open fire; it will actually burn. A steam generator is needed. In general, the purer the mash, the better for the product. Clean with bentonite, or simply through gauze (colander) and you will be happy.

A metal thickness of 1-1.5 mm is more than enough. Thick metal, this is a big price + a heavy device. And if the properties of the metal allow you to work on an induction cooker, then this is a great idea. There, even not quite liquid mash will definitely not burn and the bottom of the cube will not burn out.

9. Expect performance of a moonshine still 5.7 or more liters per hour. Yeah, put up the buckets. Think for yourself, how realistic is this? I don’t argue that sometimes you can find such numbers in descriptions, but we are educated people.

10. Wait for that collapsible steamer- this is a panacea for the smell of moonshine. Yes, steam maceration has its place, it is necessary and very interesting. Taking this opportunity, I recommend that if you need a moonshine still with a steamer, then let it be collapsible. You will be able to get drinks with green flavor and red color. BUT, don't expect a miracle. Few people know that moonshine obtained in this way is saturated with essential oils and will most likely turn white if it is diluted to 40%. That is, you may not get clear drinks. The smell is also a controversial issue. Only with a collapsible steamer will it not disappear. This is a set of events.

11. Prays for Panchenkov nozzle. Hurray, it's there, I'll get alcohol, cool! Yeah, now. If we put a nozzle into a moonshine distiller, we won’t get any alcohol. The nozzle increases the area of interaction between reflux and steam. It works only on column devices and only on those with a reflux condenser. In other devices it is nothing more than a pleasant, but useless addition.

12. Buy a device from narrow filler neck. Yes, they are cheaper, but you will be tired of washing and cleaning it. Your hand should fit into the neck.

13. Steamer without drain. From the same opera. Inexpensive, but it's like putting your pants on over your head. It's possible, but it's damn inconvenient.

So, dear distillers, I shared with you the most invaluable thing - the experience of 3638 novice distillers who have already gone through the agony of choosing a moonshine still. They say you need to learn from other people's mistakes. What do you think?

If you have any questions, call 89627664555.

A moonshine still is a complex device used to make homemade alcohol. Due to rising prices and deteriorating quality of alcoholic beverages in stores, the device has become very popular. However, to produce first-class moonshine, novice distillers must understand the design, types and features of the apparatus.

You can buy a moonshine still (distiller) or assemble it yourself. It will be difficult for novice distillers, who are not yet even familiar with the basics, to make a good device on their own. And for starters, you can pay attention to ready-made devices. To grasp the essence and meaning of the process, and subsequently, you can improve the equipment if the need arises.

Types of distillers

Each distiller has its own advantages and disadvantages. When purchasing, you should take into account the volume of the cube, dimensions, power, materials used, and design features.

Distiller components and their purpose

The design of a moonshine still depends on the type and modification of the device. The classic and most popular unit in our time consists of a distillation cube, a reflux condenser, and a refrigerator.

- A dephlegmator connected to the coil is used to filter harmful substances. Methyl alcohol, fusel oils and other heavy components are collected in the sump. The reflux condenser, installed between the still and the coil, is very important for a moonshine still, because some impurities are harmful to health.

- The refrigerator uses a coil to cool the incoming vapor. The resulting mass of alcohol depends on the quality of the component. If the refrigerator is not sealed, the alcohol may ignite.

- A distillation cube, equipped with heating elements or set on fire, is used for boiling. The element may look like a pan, can, or barrel. The main requirement for a distillation cube is tightness.

- A thermometer is necessary to control the boiling of the feedstock. If you do not monitor the temperature, the taste of moonshine deteriorates and quality is lost due to the high concentration of harmful impurities.

Classic devices, made according to a standard design, are equipped with a steam chamber or reflux condenser and a thermometer. Additional elements improve the quality of the drink and simplify the preparation process.

Operating principle of the device

Moonshine is a strong alcohol obtained by distilling a solution of ethyl alcohol, impurities and water. The quality of alcohol depends on the process technology, the quality of the mash and the amount of harmful impurities.

Stages of work

- The primary raw material placed in the distillation cube is heated. At a temperature of 63-65 degrees, low-boiling compounds, such as acetone, methyl, aldehydes, etc., begin to evaporate from the mash.

- The device, when reaching approximately 68-70 degrees, begins to release steam. The resulting ethyl alcohol enters the tube. The optimal temperature is 78-80 degrees. When the norm is exceeded, heavy oily components (fusel) begin to be released.

- Vapor substances flow through a tube into the refrigerator, where the process of condensation occurs and the vapor turns into liquid.

Since harmful substances can get into the finished product, it is recommended to include a steam vaporizer in the diagram (a reflux condenser, or a reflux condenser - that’s all, the names of the same device). Its use in the circuit of a moonshine still will reduce the amount of fusel oils and various harmful impurities. Installed between the coil and the distillation cube.

Features and design of the reflux condenser

A dry steam tank is a fairly simple device and includes a tank for settling, a pair of fittings or tubes and connecting components that ensure tightness. If necessary, you can assemble them yourself. To do this, you need a jar with an airtight screw cap.

Assembling a steamer with your own hands

Selecting a jar. The volume of the reservoir depends on the capacity of the distillation cube and should allow it to accommodate not only the accumulated liquid, but also, if necessary, flavoring and aromatic components.

Installation of fittings. Two fittings are installed in the lid, designed for steam outlet and input. One of the tubes or hoses should reach almost to the bottom of the tank, this will help prevent non-condensed vapors from entering the refrigerator.

Despite the simple device, the presence of a steamer in a moonshine still is necessary. The component serves as an excellent filter and is used in most moonshine stills. The main thing to remember is that it must be airtight.

On some models of factory stills, the liquid from the steamer is returned to the distillation cube, which helps reduce alcohol losses from the raw material. But such a design is quite complex and requires special skills and the use of technical equipment, which makes it difficult to manufacture independently.

Refrigerator Features

There are 2 types of moonshine still refrigerators. The flow-through component is made of a tubular spiral and a sealed reservoir through which cold water passes. The main advantage of such refrigerators is their small size and good performance.

The non-flowing component is made from a fairly large tank with a capacity of 20 liters or more. Spiral-shaped tubes cut into the tank through which steam passes. To operate, the tank is filled with cold water (you can even use snow and ice in the cold season), which heats up during the distillation process. Such a refrigerator is easy to create, but has a noticeable drawback. Warm water must be periodically drained or scooped out and replaced with cold water.

Tubes and hoses

For a homemade moonshine still, you can use stainless metal tubes that are welded to the other components. However, without equipment and skills, assembling such a structure is problematic. The simplest solution is to use silicone hoses with nuts or clamps. When heated, the tube material remains elastic and does not impart a chemical taste to the product.

How to choose a moonshine still?

It will be difficult for novice distillers to make a good and high-quality distiller on their own, so it is easier to buy a unit. But, many factors should be taken into account.

Distiller - moonshine. What you should pay attention to

- Material. Most often, the distiller is made of stainless steel or copper; there are examples that combine both metals in their design. Craftsmen also make devices from aluminum. A stainless steel device is considered the most acceptable due to the properties, price and significant service life of the material. The main thing is that the steel complies with the state regulations and is no thinner than 2 mm. Copper units are much more expensive, but quickly begin to tarnish. Aluminum distillers are not recommended, since the metal affects the taste and can release many harmful substances into the drink.

- Volume of a cube. The reservoir should not be filled to more than 80% of its volume. For example, only 12 liters can be poured into a 15-liter tank. If you distill moonshine no more than 1-2 times a week, this will be quite enough.

- Power. The refrigerator must correspond to the size of the distillation cube, which is not always taken into account by modern manufacturers. A novice distiller should find out not only the productivity of the apparatus per hour, but also the degree of heating and cooling rate.

- Dimensions. The minimum height of a distillation or mash column is 1 m. Such a unit is installed on a stove, which further increases the dimensions. Before purchasing a column, it is important to consider the height of the ceiling.

- Design features. There are solid and dismountable devices on sale. Modular devices are easier to clean and store. The distiller may also have drain valves located on the still, reflux condensers, etc. It is also worth taking into account the type of heating, the device is heated by heating elements below, since it is not placed on the stove.

- Automation. A distiller with controllers greatly simplifies the distillation process. However, if the sensor breaks down, the device becomes inoperable.

One of the main requirements for modern distillers is the presence of a thermometer that allows you to control the correct temperature conditions of the process.

Result:

The popularity of homemade alcoholic drinks is only increasing. Therefore, it should be approached with all responsibility. Each component of the distiller affects the quality of the resulting product, its taste and smell.

The popularity of homemade alcoholic drinks is only increasing. Therefore, it should be approached with all responsibility. Each component of the distiller affects the quality of the resulting product, its taste and smell.

There are quite a lot of recipes for making moonshine. And the technology comes down to one principle of operation, based on the distillation of mash into alcohol. To understand the entire system of processing products into alcohol-containing liquid, let's find out about the design of a moonshine still and its operation.

To obtain the final alcohol-containing product, several steps must be performed.

- Making syrup from sugar or juice of sweet berries/fruits with water.

- Combining the resulting contents with a small amount of yeast. This is mash.

- Liquid settling in heat. During the growth of the fungus, a mixture is obtained that consists of water, fusel yeast and ethyl alcohol. The resulting mass itself has a pronounced characteristic unpleasant odor, and it is not harmful. But alcohol is what you need to achieve your goal (getting moonshine).

- Separation of harmful alcohol - distillation. This stage is performed by a moonshine still, which, under the influence of different temperatures, releases alcohol, ready for consumption.

What is a moonshine still?

A moonshine still is equipment for distilling mash into raw alcohol. It consists of two containers of different volumes, a reflux condenser (dry steam tank) and a refrigeration unit (coil). In addition to these components, the moonshine brewing device is equipped with a thermometer. Thanks to it, you can control the entire process and the heating/boiling mode of raw materials. An additional element of the equipment is an alcohol meter, which is used to control the strength of the resulting product. The device operates on the principle of chemical distillation, the ultimate goal of which is to separate essential and other easily evaporating liquids - to purify alcohol vapors from associated harmful substances.

Now we have an idea of how the equipment for creating a strong alcoholic drink at home works. Let's find out how the moonshine process itself occurs.

How does a moonshine still work?

Each of the design elements of a moonshine brewing apparatus is needed to perform a specific role. Let's find out a little more about their functions.

Alembic (large equipment capacity) is necessary for mash. It is here that it heats up and rises further through the unit. It is important to install a thermometer on the cube to monitor the boiling point of its contents, without missing the process of preparing the right moonshine (of high quality and harmless to humans and their health).

Steam line (a connecting element between parts of the moonshine still structure) is needed for the transition of alcohol vapor from the large container of the structure to the cooling element.

Sukhoparnik, it is also called a settling tank - it is an intermediate vapor purifier from fusel and other heavy compounds formed during the distillation of mash. This structural element can be called a filter, which efficiently cleans the product from all kinds of impurities. Fusel oils, harmful resins, methanol and other harmful components settle on the walls of the vessel when cooling - this is the main function of the steam tank (selection and sedimentation of harmful liquid fractions).

Note. The settling tank is also used to saturate the final product. A natural flavor (citrus or other) is added to it, thanks to which the moonshine becomes more pleasant to the taste.

Fridge (coil)– a place for condensation of steam into an alcohol solution. The design of this moonshine element is not as important as the temperature that provides the condensation effect. A temperature of 30% Celsius will be sufficient.

In this unit, alcohol vapors come into contact with cooled walls and condense into a liquid state, in which they move into a receiving container.

Pay attention. The temperature can be reduced to the desired degree by circulating cold water or using a special container in which the water is periodically replaced with clean water.

As you can see, the process of distilling mash is carried out in stages and at different temperature conditions. To obtain a high-quality product, you need to limit the boiling temperature of the mash, since when the vessel is heated, the process of evaporation of not only harmless liquids begins:

- in the temperature range from 65 to 68 degrees Celsius, boiling and evaporation of light impurities (the so-called “pervach”) occurs. They are poisonous and completely unsuitable for consumption and can cause irreparable harm.

Note! This part need not be drained only in cases where the final product will not be used for oral administration;

- when the mark on the thermometer reaches 78 and higher (up to 85), ethyl alcohol begins to boil. It is in this range (preferably at its lower level) that distillation should be carried out.

Note. At temperatures above 85 degrees, heavy products called fusel oils begin to evaporate. Their use can be harmful to human health, they worsen the quality of the final product and its flammable properties. If the boiling temperature reaches 100 degrees, then the water itself will begin to boil, and moonshine will lose all meaning.

Afterword

Moonshine brewing is an art. Knowledgeable people monitor every stage of alcohol preparation and are interested in obtaining a high-quality product that is harmless to the human body. Here are some tips from experienced moonshiners:

- for normal operation of the moonshine still, it is important to ensure the absolute tightness of all its components, connecting and additional (thermometer, alcohol meter) elements;

- Do not under any circumstances spare the “first drink”: it should not be left for further distillation and is dangerous to drink. Drain it into a separate container and can be used for external use;

- home-produced alcohol that is suitable for consumption is alcohol formed under the influence of a temperature from 78 to 85 degrees, preferably up to 80;

- Do not heat the moonshine still above 85 degrees Celsius. At this boiling point, heavy harmful substances - poisonous fusel oils - evaporate with alcohols.

- when alcohol begins to drip from the refrigeration unit (from the coil), you can stop the moonshine;

- Regularly, after each distillation of mash, it is necessary to wash the vessels and steam line.