How to perform the second distillation of moonshine - step-by-step instructions. Features and process of preparing alcohol through a moonshine still How to infuse moonshine before the second distillation

Most people who smoke moonshine at home are, one way or another, interested in obtaining a high-quality alcoholic drink. The most effective way to achieve this goal is the second distillation of moonshine. The alcoholic drink obtained in its process is often called double moonshine.

Secondary distillation of moonshine can be carried out regardless of the feedstock that was used to produce the mash. The specific recipe, as well as the specifics of the distillation process, also do not matter. Moreover, we can distill a second time even a drink prepared much earlier.

Repeated distillation of moonshine can significantly improve its quality and organoleptic properties (taste and aroma). In addition, it itself is an effective method of additional purification of the distillate. Naturally, such a result can only be achieved by using the correct technique, observing proportions and sequence of actions.

The right technology

The second distillation consists of several sequential steps that must be followed. They need to be completed step by step and all the described operations must be performed accurately.

1. Diluting raw alcohol or primary moonshine with water.

Double distillation of moonshine is made from a product whose strength does not exceed 19-21 degrees. Ignoring this step is unacceptable. Otherwise, when distilling again, we may encounter a fire in the moonshine still. In addition, the higher the strength of moonshine, the stronger the bond of ethyl alcohol with harmful impurities and fusel oils. Thus, secondary distillation will not have the desired result and will not allow for high-quality purification of the distillate.

First of all, we need to dilute the moonshine. It is also of great importance what kind of water we use to do this. Of course, the tap or boiled version will not suit us. It is best to use cool well or spring water. As a last resort, let the water supply stand for 2-3 days.

Before diluting moonshine, measure its strength using a household alcohol meter. Only after this add the required amount of water.

2. Proper cleaning.

The feasibility of this step depends on the raw materials. So, if we made sugar or cereal mash, then the product obtained from it needs similar purification. To carry it out, I recommend using skim milk, charcoal or egg white.

Berry and fruit moonshine, as a rule, is not further purified. Otherwise, we may lose the pleasant taste and smell that the drink received from the original raw material. Thus, there will be no point in making moonshine from any specific fruit or berry.

3. The distillation itself.

The final stage does not have any distinct specifics. You can proceed in exactly the same way as when distilling moonshine for the first time. True, with one caveat. The product obtained in this case must be divided into fractions. We are talking about “heads”, “body” and “tails”.

The fact is that the first exit or “heads” consist entirely of harmful substances. In particular, acetone. They have a pronounced unpleasant odor and make up the first 9-10% of the yield. Remember, drinking this liquid is strictly prohibited!

The main part of the output or “body” is the same double moonshine for which this process was started. Controlling it is quite simple. It is necessary to measure the strength of the stream. At the moment when it drops below 40 degrees, the collection of the “body” is considered complete.

Everything we can get below this cutoff is “tails”. In turn, they consist almost entirely of fusel oils. You can not select them at all, or you can collect them and use them for the next batch of mash.

This completes the preparation of double moonshine with a strength of 60-70 degrees. The only thing you can do to improve it is to let it sit for 3-5 days.

Is additional cleaning necessary?

Of course, perfection knows no boundaries or limits. However, in this case, any manipulations aimed at cleaning the resulting distillate are meaningless. The thing is that at home we simply do not have any tools or techniques that allow us to clean moonshine even better.

Remember, purifying moonshine only makes sense between the first and second distillation.

Does the third distillation make sense?

This question can be answered with a clear negative answer. The third distillation of moonshine makes no sense.

There is a simple explanation for this. The fact is that the distillation process allows for a rather rough separation of substances. If we are talking about better purification, then a much more precise division of the resulting product into fractions is required.

No matter how accurately we distill, both the “heads” and the “tails” in a certain amount will still remain in the “body”.

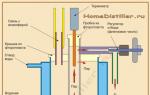

The only existing solution that you can use at home is a moonshine still with a reflux condenser. Such equipment already makes it possible to obtain deeper and higher-quality fractional division. But the steamer, contrary to popular belief, is not our help in this matter.

Purification of moonshine after the second distillation is a process that differs in a number of nuances. Not everyone purifies moonshine after reprocessing; some moonshiners consider multiple distillations to be the best filtration method for the distillate.

To save time and improve the quality of the alcohol, purification can be done before re-distillation. It all depends on the desire of the distiller, as well as on the goal that he pursues.

The question of how to clean moonshine arises even before it is sent for recycling. This is necessary in order to improve the quality of the drink, make its taste softer and at the same time rid the alcohol of harmful fusel oils.

Second distillation of mash

The second distillation takes place in several stages, this helps to synchronize the actions and at the same time improve the quality of the distillate.

So, the principle of operation:

- Before the second distillation, the moonshine must be diluted. This is done in order to reduce the strength of the drink, as well as to destroy the molecular bond between fusel oils and alcohol. Dilution will also help to avoid problems with the device: if you distill undiluted alcohol, it can explode during the distillation process. Moonshine is diluted to 20 degrees, and then proceed to the next stage.

- Purification is another step in the processing of alcohol-containing liquids. At home, you can clean moonshine using potassium permanganate crystals, activated carbon tablets or charcoal for igniting barbecues. But the easiest way is to pass the finished drink through a carbon water filter. It is enough to pour the distillate into the filter jug 1-3 times to clean it of impurities.

However, you can even remove impurities from alcohol by using bread. It has a porous structure, for this reason it absorbs all harmful substances like a sponge.

The purification of the drink takes place according to various schemes. If you use potassium permanganate crystals to remove impurities, you will have to prepare a solution. 2 grams of crystals are diluted in warm water (no more than 300 milliliters). Potassium permanganate must be dissolved so that there are no lumps left. Then the product is diluted with the prepared solution.

The drink undergoing purification is left in a dark place; the whole process will take at least 10 hours. Then, when the potassium permanganate precipitates, you will have to filter the alcohol using a self-made filter.

You can pass purified moonshine through a cotton-gauze filter or use flannel. This will help rid the liquid of any remaining magnesium permanganate.

Once purification is complete, distillation can begin.

Recycling alcohol will help:

- Improve the quality of the drink.

- Remove all fusel oils, aldehydes and esters from it.

- Increase the strength of the moonshine to 60–70 degrees.

The first distillation leaves some fusel oils in the alcohol, for this reason it may have an unpleasant odor and taste. Repeated processing will improve the quality of the drink, it will help eliminate fusel and, despite the fact that the moonshine was diluted before processing, the second distillation will significantly increase the strength of the drink.

During recycling, a number of manipulations will have to be carried out that will help improve the quality of the drink.

Distilling moonshine for the second time

Before distillation, it is worth preparing the alcohol for the procedure; after purifying it, you need to pour the moonshine into the distillation cube and proceed directly to the process.

When processing alcohol, you will have to again separate the “heads” from the “tails”. Separation into fractions is necessary because this will help to significantly improve the quality of the distillate. The “body” will be about 85% of the total volume of the distilled product.

The first 8–10% of the total volume of processed alcohol is the so-called primary alcohol. You shouldn’t drink it, even though the primary substance was already taken away during the first distillation of the mash. This fraction contains a large amount of fusel oils. The “heads” have an unpleasant odor; for this reason, distillers with experience begin to select the “body” when the moonshine loses that very pungent aroma.

When the selection of the “body” is completed, it is worth starting to cut off the “tails”. This happens when the strength of the drink drops below 40 degrees.

"Heads" can be used exclusively for technical needs. This product is hazardous to health and can be used to clean surfaces. But the “tails” can be poured into the mash - this will help improve its quality, and most importantly, increase the strength of the mash, and therefore the distillate, several times.

The “tails”, as well as the “heads”, contain a large amount of fusel, for this reason you should not drink them. The selection of this fraction continues until the strength of the drink drops to 19–20 degrees.

Repeated distillation of the distillate ends with the selection of “tails”. After this, the moonshine is sent to a dark place, it needs to brew a little.

Why is filtering needed?

Moonshine is not always purified; some experts believe that repeated processing makes the alcohol so pure that it does not need additional filtration procedures. The experts are partly right, but there is one thing.

One way or another, some amount of fusel remains in the moonshine. Although its strength is high, this indicator may not be enough for the production of noble drinks.

An example is a rectifier - this device is used to produce raw alcohol at home, the strength of which can reach 96 degrees. This product is used to make liqueurs and tinctures.

In what cases is it worth purifying moonshine after re-distillation:

- If you plan to make cognac, brandy, Calvados, rum, etc. from the resulting distillate in the future.

- If the product will be used to make liqueurs and tinctures.

Is it necessary to purify moonshine that is simply going to be drunk in its finished form? The answer to this question is negative, since the quality of the drink is already very high. Additional filtration will improve the characteristics of the alcohol, but it will be difficult to notice such minor changes.

What another treatment or distillation benefits will give:

- It will help improve the taste of the drink and eliminate the remains of fusel.

- It will refine the distillate and allow it to be used for making cognac and whiskey.

In order for alcohol to acquire that pleasant smell, it must be supplemented with aromatic substances. Flavorings will give the moonshine a taste and smell; berries and fruits, spices and herbs can be used as such substances. Additives will prepare alcohol for further processing and help turn ordinary moonshine into an elite product.

The easiest way to purify moonshine is to infuse it with milk. Pour a glass of milk into a 1.5-liter container with moonshine. It is desirable that the product is unpasteurized.

The container is placed in a dark and cool place and the drink is infused for 7 days. Then the alcohol will have to be filtered. But before you clean it of lactose residues, you will have to make a filter.

This device is not complicated in design; to assemble it you will need:

- a 1.5 liter plastic bottle with a tight lid that fits in size;

- activated carbon tablets or charcoal for igniting barbecues;

- cotton wool and gauze, as well as scissors and an awl.

You will have to make a funnel from the bottle, cutting off the bottom evenly so that there are no nicks left. Afterwards, a hole is made in the lid using an awl.

Tablets or coal are crushed, placed in cotton wool and the device is fixed with gauze. Then they start filtering. It is advisable to change coal, gauze and cotton wool regularly; moonshine will have to be passed through a filter 3 to 5 times.

After the alcohol is infused with milk, it can be used to make noble drinks such as rum, brandy, cognac and whiskey.

Little tricks

There are several nuances that are worth knowing before you start distilling moonshine. This will dispel doubts, and at the same time understand whether it is necessary to run the drink through the distiller again.

So, what does a moonshiner need to know:

- Recycling will take a certain amount of time. It will take 2 to 3 hours to clean alcohol from impurities.

- Even repeated distillation will not help you obtain raw alcohol at home. This can be done using a rectifier.

- Braga made from dense wort (berries, fruits, etc.) will not be distilled again. Processing will remove the pleasant smell and affect the aroma of the drink.

- Even alcohol that was distilled a long time ago and has been stored in the cellar or refrigerator for several months can be distilled twice.

- Due to the fact that you will have to select the “heads” and “tails” twice, the amount of distillate will change. Volumes will decrease by 20%.

Many fans of making mash drinks at home are experimenting with cleaning, wanting to improve the quality of the product in one way or another. The second distillation is the main way to increase the strength of moonshine, increasing its strength.

But cleaning after repeated processing is carried out at the request of the manufacturer or consumer. It cannot be called a mandatory procedure, but repeated filtration can be resorted to if you plan to turn moonshine into cognac or whiskey, and also if the quality of the drink is in doubt.

You can improve the quality of moonshine by removing all foreign impurities from it. And this can be done if another additional fractional distillation is carried out. The resulting product was called double moonshine. To prepare it, you will need to spend a little more time than usual (about 3-4 hours from the first distillation). However, the end result will be the purest distillate without any odors or harmful impurities.

Absolutely any moonshine can be double distilled. It makes no difference what raw materials it was created from. It is important to know that even a drink that has been kicked out for a long time can be refined in this way. Let's look at how to properly distill moonshine for the second time at home?

Why do you need a second distillation of moonshine?

Previously, many people in Rus' indulged in drinking. People simply made their own mash and consumed it with pleasure. At that time, no one was familiar with the distillation method. And the mash was prepared from everything that was on hand in the house or grew in the garden.

Today, all experts loudly insist that drinking mash is harmful. After all, it contains acetone, fusel oils, and aldehyde. This is not the entire list of substances, the accumulation of which in the body leads to death. Therefore, abusing the drink is incredibly harmful.

Today it is quite simple to rid mash of unnecessary impurities. This requires a second distillation of the moonshine. As a result, the product becomes clean and harmless.

Three important steps in the process

Each specialist who distills moonshine has his own important rules, tricks, secrets and nuances. Re-distillation must be done efficiently. To do this, all the main steps are followed:

Dilution

No matter what recipe for an alcoholic drink is chosen, the strength of the raw material before distillation should be within 35-40%. Otherwise, there is a chance that the equipment used will deteriorate, and real fireworks will occur in the kitchen. In this regard, before placing the raw material into the device, it must be diluted. This is necessary to:

- The alcohol vapors really did not rupture the moonshine still;

- It is more efficient and faster to separate ethyl alcohol from heavy and harmful impurities. If the strength of the raw material is above 40%, then the molecular bonds in the raw material will be stronger.

Moonshine must be diluted with filtered water. It must be cool. You can make it this way by placing it in the refrigerator first.

The fractional procedure for diluting raw materials implies that water is added gradually. In this case, it is recommended to measure the strength each time using an alcohol meter. Ideally, if you bring it to 35%. It is necessary to add water to moonshine, and not vice versa.

Cleaning

Fractional distillation also involves careful preliminary purification of moonshine. Several methods can be used. To do this you will need:

- filter cardboard or paper;

- potassium permanganate;

- Activated carbon;

- charcoal.

If you intend to use special paper, then cleaning is very simple. You need to put the sheet in a funnel, and moonshine is poured into it. It is necessary to pour the drink as slowly as possible so that the filtration occurs as efficiently as possible.

The cleaning recipe using manganese requires care and patience. It is very important to maintain all proportions and follow the steps consistently:

- For each liter of raw material, take a solution of 50 ml of hot water and 2 g of potassium permanganate. As soon as the pharmaceutical crystals dissolve, all this is poured directly into the moonshine;

- then the raw material settles for at least 10 hours;

- as a result, sediment should remain at the bottom of the container;

- the next stage is filtering the moonshine through cotton wool or flannel, which is placed in a funnel. Alcohol is filtered through it.

Only after such filtration is the moonshine re-distilled.

The final stage is the direct distillation

First, the moonshine still is prepared. It is thoroughly washed and then carefully and correctly collected. The second run is carried out in the same way as the first. In this case, the end result will be slightly less finished drink.

Despite the purity of the feedstock, “heads” and “tails” occur during re-distillation. That is why you should pay attention to what comes out of the device. If necessary, you will need to separate the so-called “body”.

It is important to consider several important points when carrying out the procedure:

- In the total volume of the product, about 10% will be “heads”. This fraction can be used exclusively for technical purposes: disinfection of objects, cleaning of various surfaces. You can't drink it, it's very harmful.

- It is important to monitor the “turnovers” during distillation. This is done using a conventional alcohol meter. If the strength drops to 45%, you will have to prepare a special container in which the “tails” will be collected.

- You can determine the moment of collecting the main part of the valuable moonshine using your sense of smell. Having collected 10% of the product, you just need to smell it. If there is no strong, pungent odor, then double moonshine has already started and is ready for consumption. Most often, the main part is 80% of the total volume. However, there are high-quality powerful units that produce up to 95% of the “body”.

- The “head” is useful for some household needs. But the “tails” are an assistant in increasing the strength of new raw materials. They are simply added to the mash in order to make another batch of the purest homemade alcohol in the future.

Additional cleaning of the finished product

Once the entire double distillation process is completed, you can:

- Additionally purify the moonshine;

- Elevate it so that it tastes better. For this purpose, special aromatic additives that are sold in stores are suitable. You can add fresh berries and fruits to the product;

- Enjoy the result in its purest form. You can dilute the drink with water to make it softer.

The recipe for additional purification of the resulting drink may be different. You can use natural milk. This is the most common method.

For 1.5 liters of alcohol you will need about a glass (250 ml) of milk. It is poured into moonshine and left alone for a week. Experienced professionals who have been making high-quality moonshine for years are confident that this process will require milk “from the village.” Only a natural product can cope with the task. The result is the purest moonshine even at home.

However, the cleaning doesn't end there. Next, pass the alcoholic drink through a funnel with a layer of activated charcoal or charcoal. It is not recommended to use potassium permanganate. This time, this option can significantly harm your health.

After additional cleaning, you can refine the drink. You can use a recipe for making cognac or a healing tincture for this.

Cognac from double moonshine

The recipe for making cognac is easy to follow. It is enough to put the peels of several lemons into a three-liter jar of alcoholic drink. A tablespoon of black tea (without aromatic additives), 3 cloves, 3 peppercorns and bay leaves are also added there. In addition to seasonings, 2 tablespoons of sugar and a pinch of vanilla are mixed into the future cognac. Cover the finished mixture with a lid and place in a dark place. In exactly 10 days, the noble drink will be ready for consumption. You can set the table!

Recipes for refining moonshine

The art of cooking is not only the preparation of original dishes, but also the creation of a variety of drinks, including the refinement of moonshine. Drinks with bitter tastes are known. However, moonshine can also be given other flavors. Each moonshiner has his own signature recipe. Here are just some of the “seasonings” that are added to moonshine after the second distillation:

- Rosemary – 1 gram per liter;

- Orange zest – 100 grams per liter;

- Nutmeg – 3 grams per liter;

- Vanilla (to obtain a bitter taste) – 2 grams per liter;

- Ginger (for pungency) – 10 grams per liter.

The recipe assumes that the drink must be infused with additives for at least 2 weeks. Only then can you drink it.

To make moonshine sweeter, you can add to it:

- Syrup, which is prepared from sugar and water in proportions of 1 kg per 1 liter, respectively;

- Jam.

Having added a sweetener to the moonshine, the drink is heated over a fire until gases begin to be released from it. After this, it needs to be filtered. The finished moonshine is poured into containers and infused for 3 days.

You can add color to the moonshine. The recipe implies that it is best to color alcohol before filtration, immediately after re-distillation:

- The red color comes from adding dried blueberries to the drink;

- The yellow tint comes from lemon balm and mint. You can use celery or parsley for this;

- You can make moonshine golden by adding saffron, walnut partitions or orange peel;

- The brown tint is obtained by adding unshelled pine nuts or a small amount of good loose leaf tea (a large spoon for 3 liters);

- Moonshine gets its blue hue thanks to the bright flowers of cornflower;

- You can make a green drink by adding the boiled juice of fresh onion feathers or ordinary leaves from blackcurrant bushes.

Herbal additives provide not only a certain color and a wonderful aroma, but also softness, which makes drinking such alcohol even more pleasant. And secondary distillation makes it possible to make alcohol of high quality and completely safe. Taking care of your health, it must be done every time you make moonshine at home. At the same time, you can experiment with different tastes, aromas and colors of the drink. For particularly high-quality purification, you can distill it again and get triple-distilled moonshine, in which case the finished product will be even better.

Moonshining has long ceased to be a reprehensible phenomenon. If previously they were chasing mash to find an additional source of finance or to gain access to surrogate alcohol, now the situation has changed. Moonshining has now become like a hobby or a homemade process. A huge database of recipes and modern equipment allow you to get high-quality alcohol of any kind at home. Nowadays, moonshine is no longer associated with the muddy, vigorous old man’s mumbo jumbo. Making homemade alcoholic drinks is a non-trivial hobby and an original way to please guests during a feast.

Why distill moonshine a second time?

Repeated processing of the mash is needed for more thorough filtration, which will remove excess odors, soften the taste of the drink, and improve the visual characteristics of the liquid.

Additional filtration does not take longer than three hours. The process uses a moonshine still and a certain amount of raw materials. Drinking mash that is not properly filtered is very harmful. As you know, moonshine is conventionally divided into three fractions, popularly called “tail”, “body” and “head”.

- The “head” is the so-called “primary material” released from the apparatus during distillation. However, heads besotted with “pervach” are unlikely to think about the fact that this fraction is composed primarily of acetone.

- The “tail” is even more harmful fusel oils, so repeated distillation of moonshine is required to cut off the “head” and “tail” of the “green serpent”, leaving the “body”, which is ethyl alcohol 76 degrees.

This process is clearly structured into three stages - dilution with water, filtration, and the second distillation of moonshine itself.

Dilution

The strength of the mash before re-distillation should not exceed 40 vol. High strength can cause irreparable damage to the moonshine still. In addition, water promotes the effective separation of alcohol from other fractions. Water is poured into the raw materials in doses; the process must be constantly monitored using the readings of an alcohol meter. The optimal strength of the liquid should be in the range of 35-37°. Moonshine must be diluted with filtered water, which must first be cooled in the freezer.

Getting rid of toxic fractions involves using a system of filters of various degrees of purification. Paper, activated and charcoal, and potassium permanganate can be used as adsorbent materials at different stages of cleaning. You can buy special filter paper for water and use it inside the funnel through which the moonshine is poured. You can repeat the procedure several times, using paper as a coarse filter. To filter moonshine with potassium permanganate, you need to prepare a filter solution in advance. 2 g of manganese crystals are added to 50 ml of boiling water. After dissolving the substance, the solution is poured into a container with moonshine. For cleaning with manganese to be successful, the raw materials must sit for 10-11 hours. Manganese will precipitate “base” fractions to the bottom of the container, after which they only need to be removed.

Coal cleaning is the most popular. For filtering moonshine, regular activated one from a pharmacy may be suitable, but it is better to use special adsorbers for drinking water filters, gas masks, gas analyzers, and special winemaking charcoal.

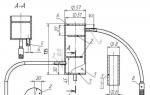

There are two algorithms for carbon filtration - straining the mash through a filter, or immersing the coal in a container with the distillation product. Methodology for manufacturing a primitive but effective filter:

- Cut off the bottom of the plastic “one and a half” and make several holes in the cork.

- Then the neck of the bottle is tightly packed with cotton wool, on top of which a thin layer of filter carbon chips is laid out. It is better to replace the carbon layer with a new one after each filtering of the liquid.

There is an option for purification through a regular drinking water filter. True, each share of moonshine must be passed through the filter five times.

The most “passive” option is to place coal in a container with raw materials. Coal chips are added at the rate of fifty grams per liter of liquid. Adsorbing processes last about two hours. After the period has passed, the coal chips must be replaced with new ones. The process is repeated 2-3 times. Cleaning with charcoal is carried out exclusively before the raw materials are infused with herbs and roots, otherwise the charcoal will “take away” the aroma and shades of taste. Coal is the most convenient way to cut off the “head” and “tail”.

Second distillation of moonshine

The immediate second distillation begins with the preparation of the moonshine still. During secondary distillation, the amount of the final product increases due to the purification procedures carried out in advance. In addition, the “secondary” process is easier and the process is completed quite quickly. Despite thorough filtration and additional purification, impurities of heavy fractions may still remain in moonshine. But they will be separated and the moonshiner will be able to use them as he pleases (preferably for technical purposes). Secondary distillation requires careful detection of alcohol meter readings. If the strength drops below 42-45 vol., then intensive formation of fusel oils will begin in the liquid.

If there is no pungent odor, this means the formation of a high-quality double-purified product. Standard machines produce up to 80% of a quality product; powerful moonshine “gadgets” are capable of squeezing out 95% of excellent filtered moonshine. You shouldn’t get rid of the tails right away - it’s better to save them for further topping up in the mash if you want to increase the strength. When adding “tails” you will need to further pass the mash through adsorbents.

Additional processing of raw materials

After double distillation, you can begin the procedure to improve the aromatic and taste properties of moonshine. The modern moonshine market offers various aromatic additives for adding to filtered raw materials. Lovers of natural products resort to the use of berries and aromatic herbs. Herbal additives will not only improve the visual appearance of the drink, but will also add flavor notes and remove excess bitterness.

A proven thing is adding milk to the finished product. The latter has pronounced softening properties and neutralizes excessive strength. 300 ml of not pasteurized, but natural village milk is added to one and a half liters of moonshine and allowed to brew for 12-14 days.

- this is an actual process in modern moonshine brewing. After all, we are talking about a homemade product, in the production of which high-tech factory filtration methods are not available. Therefore, it is better to once again insure the health of yourself and your loved ones by subjecting the product to secondary processing. Moreover, this process will not require significant effort. But you can always surprise your guests and please yourself with the purest home-made alcohol. The excellent taste without bitterness and the aftertaste of alcohol and fusel oils will be appreciated by everyone who tries wonderful drinks from the home cellar.

Video instructions

In a home distillery, you can make alcohol that will compare favorably with store-bought alcohol in its purity and taste. But this is achievable only if you approach the production process wisely. Only repeated chemical cleaning and second distillation of moonshine guarantee the removal of the maximum possible amount of harmful impurities.

In general, double distillation of moonshine at home is not necessary. However, most distillers with significant experience and knowledge in the field of chemistry still recommend subjecting homemade alcohol to multi-stage distillation. In some cases, re-distillation of moonshine is necessary:

- during chemical cleaning with certain substances (potassium permanganate, soda, sodium hydroxide, and so on);

- when infusing a drink on plant materials, which may subsequently deteriorate (berries, fruits);

- with obviously poor taste.

Under these conditions, secondary distillation of moonshine is necessary, otherwise the drink can be simply hazardous to health.

What factions can be expelled a second time?

Quickly navigate to the article

During primary distillation we obtained three fractions. The most valuable is the central one - the “body”. We send her to the second distillation of moonshine. It contains the least amount of harmful impurities that are difficult to remove. This is what should be distilled a second time.

However, some distillers also subject the tails fraction to secondary and tertiary processing. They can also be brought to mind, especially if the equipment allows. A double distillation moonshine must, at a minimum, allow temperature control to obtain a pure product.

Preparatory manipulations

Also, before distilling moonshine a second time, you should first prepare it. The first thing you need to do is to reach the desired strength:

- the “body” fraction is diluted to 20°;

- “tails” fraction - up to 10°.

It is better not to use purchased charcoal for barbecue - it may contain impurities that re-distillation of moonshine cannot cope with, but to use one made by yourself. The recipe is very simple:

- we cut birch or oak into round pieces 3–5 cm thick;

- Keep it warm for 2–3 weeks to remove excess moisture and resins;

- Place the rounds in a cauldron with a lid and bake for 1.5–2 hours.

- cool together with the pot;

- remove small fractions (dust).

This is the most environmentally friendly way. But since we are planning a second distillation of moonshine, we can use more - saponification with alkalis, adding vegetable oil, potassium permanganate, soda, and so on.